Services & Technical

Expertise

- Alloys / Brasses

- Casting & Forging

- Brass Machining

- Plating & Finishing

Contact us about development or new brass products.

Providing optimal solutions to our clients. The company also provides completed and assembled products, as well as parts, to other factories.

EXIPRO Alloys / Brasses

EXIPRO produce products from, and has access to the complete range of, alloys from its in-feed material alloy specialist Non-Ferrous metals

FAQs

Got a question about EXIPRO Alloys / Brasses? We’re here to help.

-

Does EXIPRO have expertise in using Dezincification-Resistant Brass (DZR)?

EXIPRO has expertise in the processing DZR Brass

Description

These specialty brass alloys are resistant to dezincification that might occur in potable water or other aggressive water environments very typical throughout Africa and many other countries

Typical Uses

- Plumbing & safety Valves

- Ball valves

- Plumbing Fittings

- Taps

- Faucets

- Float valves

Processing

EXIPRO has vast experience in brass alloys and processing via

- Gravity die casting

- Forging

- Machining from rod stock

The following extrusion Shapes are common

Round, Square, Rectangular, Hexagonal, Specialty Profiles

-

Does EXIPRO use a range of different brass Materials?

Yes, many other alloys are processed by EXIPRO.

EXIPRO has access to the full range of alloys from its infeed material alloy specialist (https://nfm.co.za/tech-specifications/ ) and Non-Ferrous metals and technical selection advice can be given on most enquires provided detailed application data is available from the customer.

-

What industrial products are made from Dezincification-Resistant Brass (DZR)?

Here is a list of some of the industrial products:

Contact EXIPRO for more information

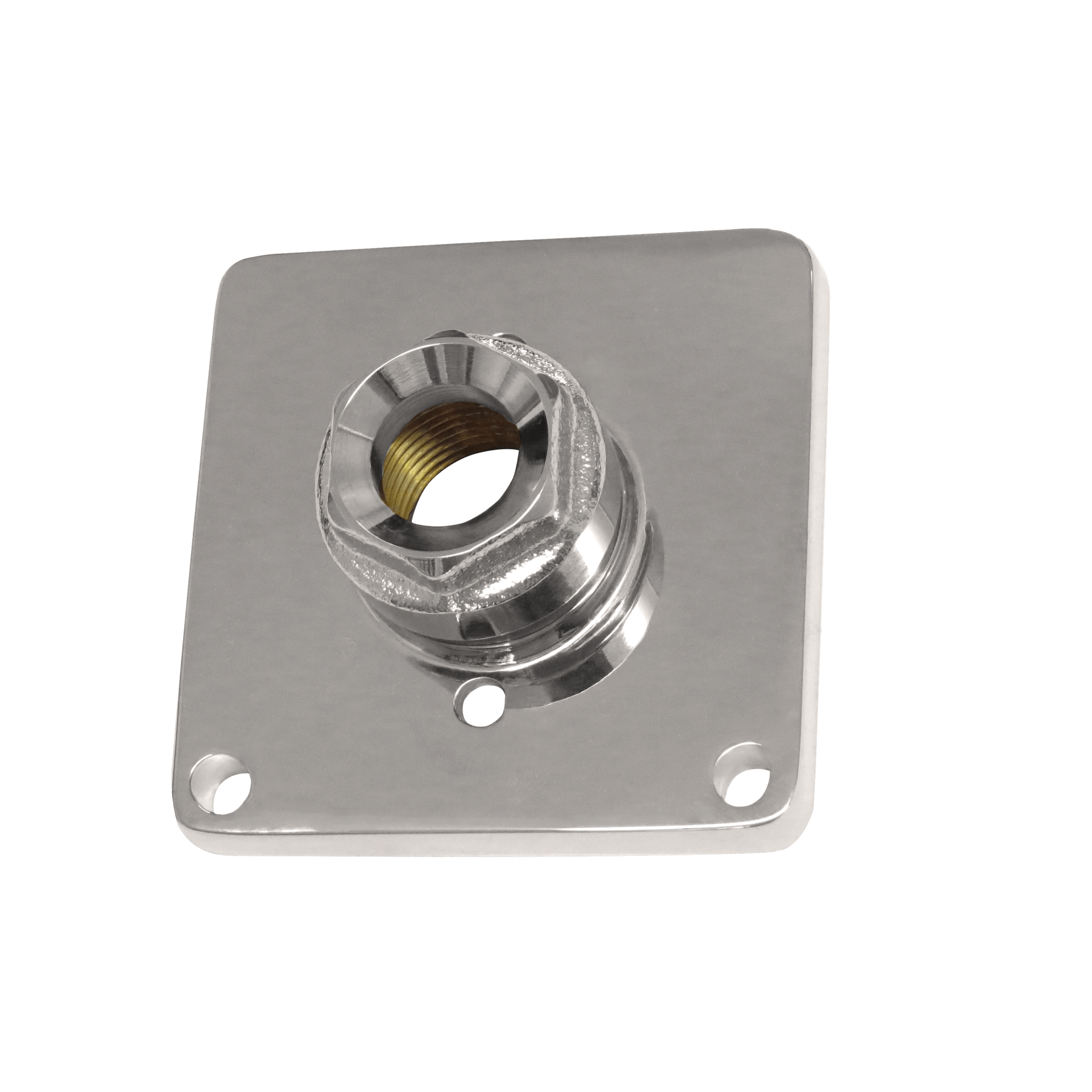

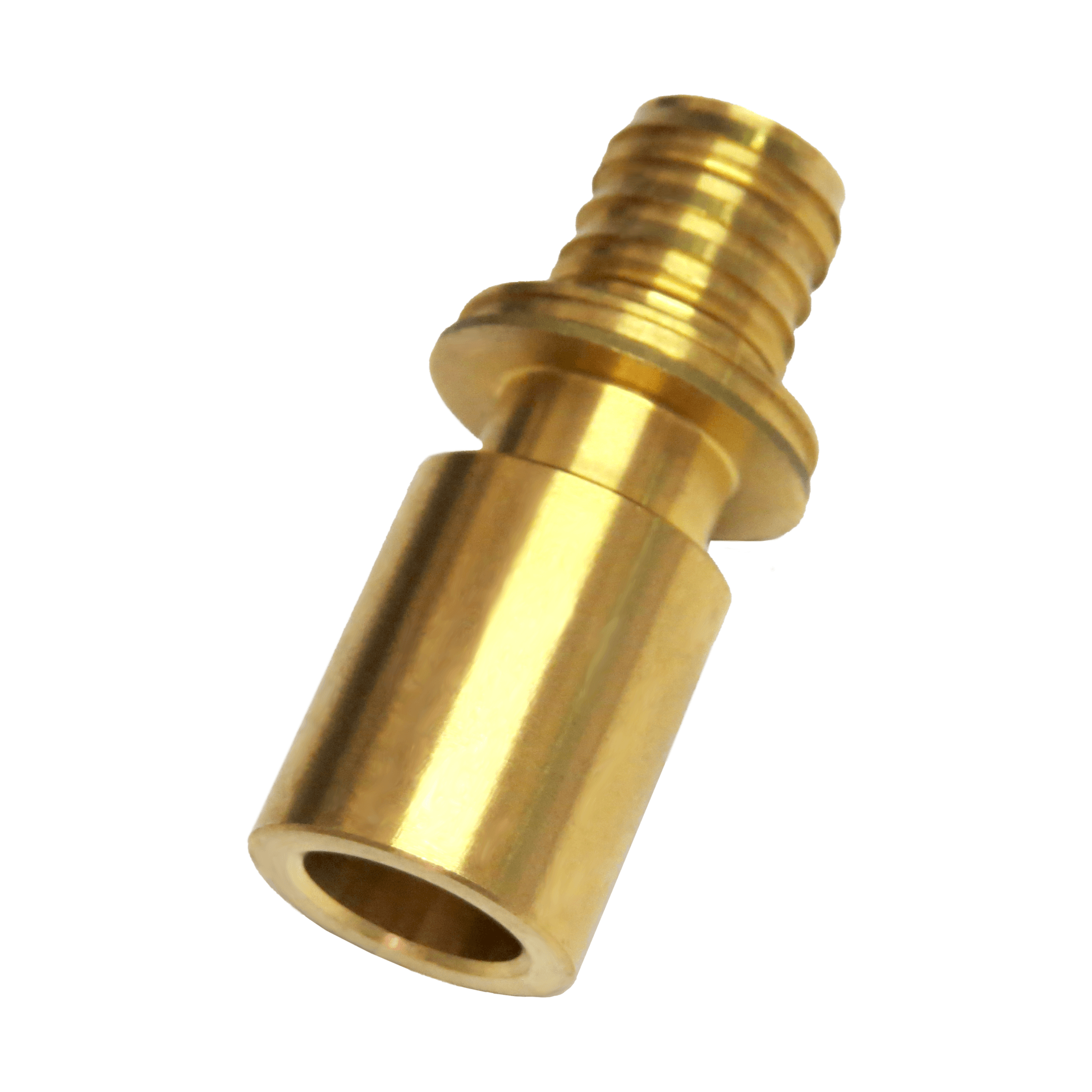

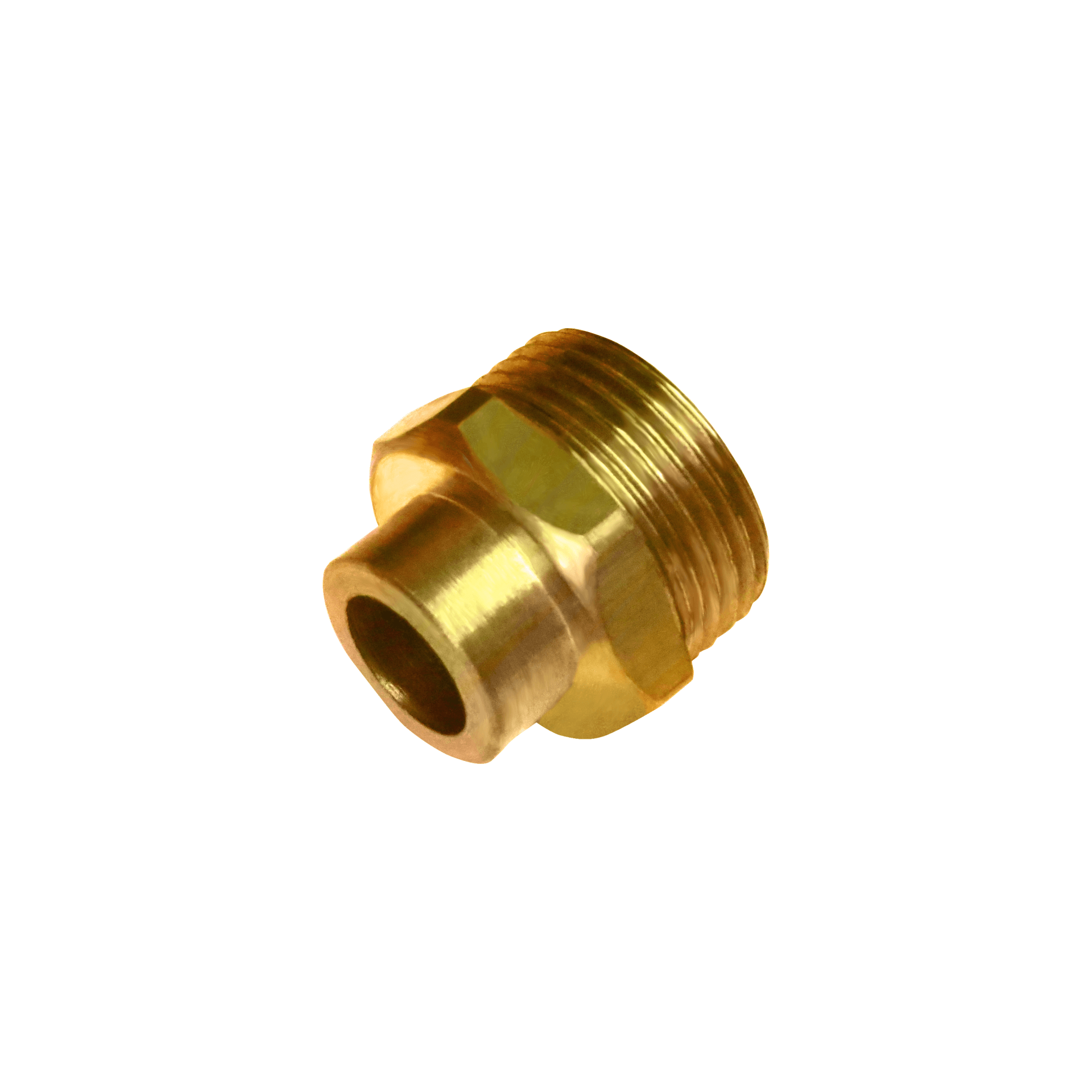

Faucet Components

Fluid Connectors

Nozzles

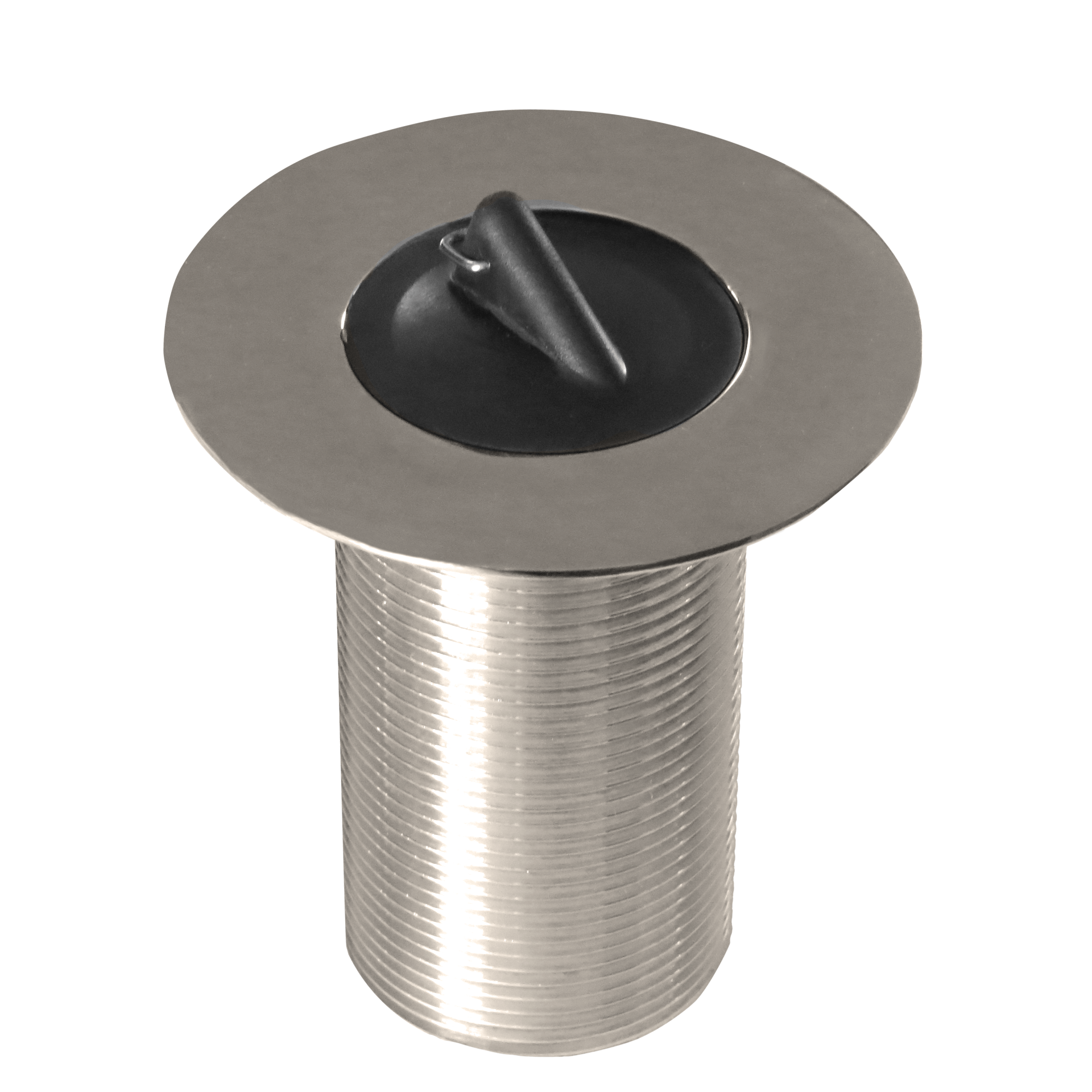

Plumbing & safety Valves

Ball valves

Plumbing Fittings

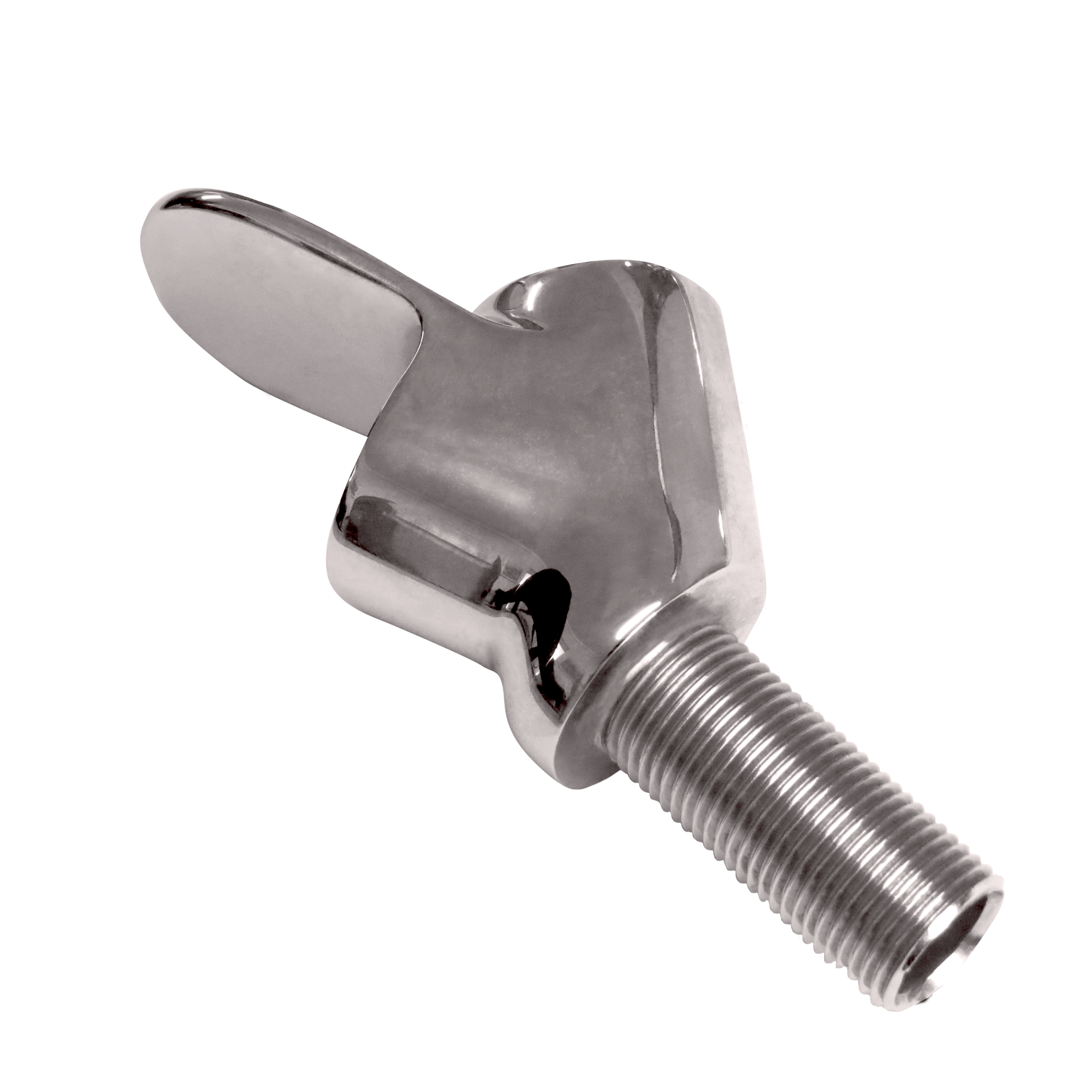

Taps

Faucets

Float valves

EXIPRO Casting & Forging

EXIPRO has extensive experience in assisting customers in choosing between casting and forging and always openly discusses the pros and cons with customers.

FAQs

Got a question about EXIPRO Casting & Forging Methods? We’re here to help.

-

What Die Casting methods does EXIPRO use?

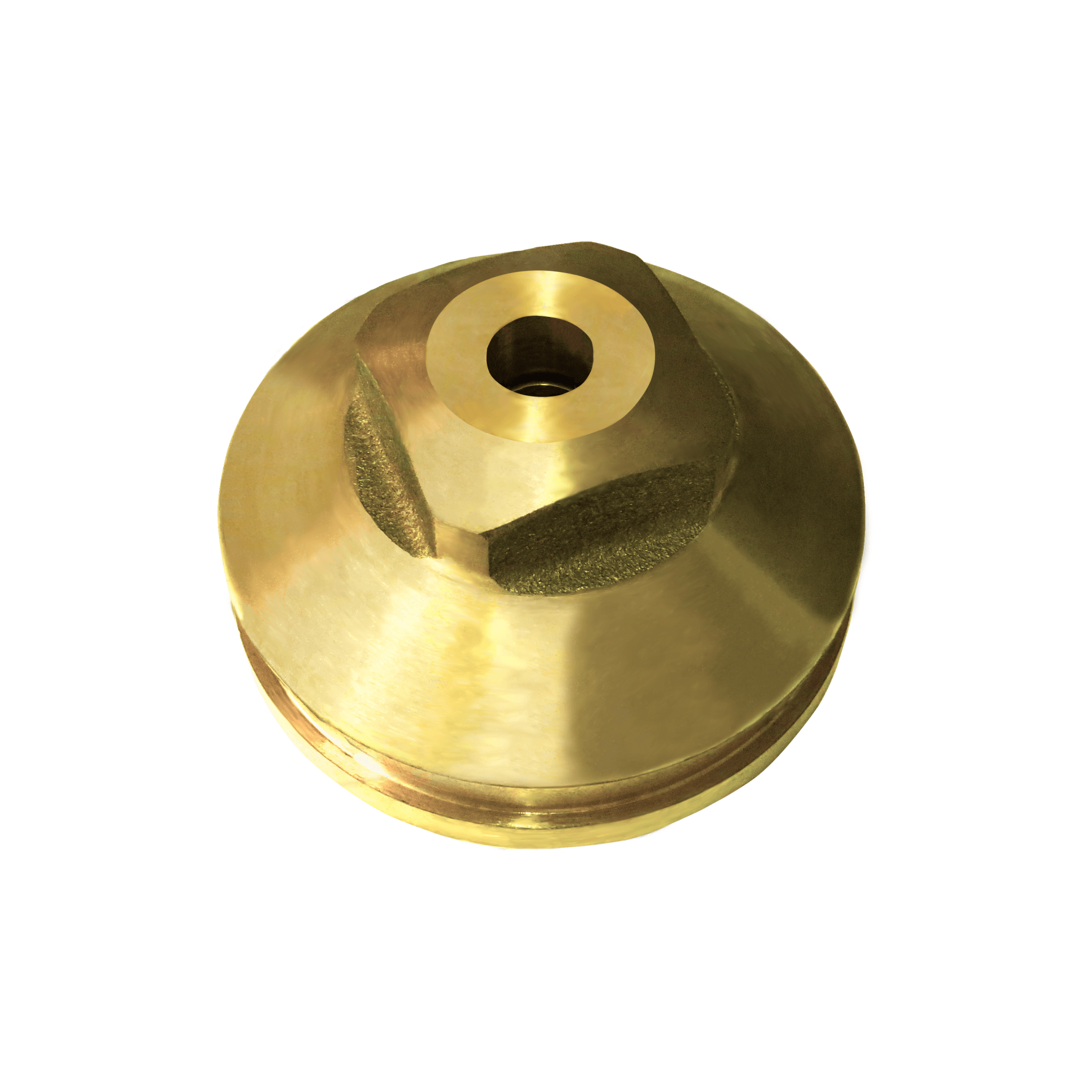

Gravity Die Casting

The Gravity Die Casting process utilises die/moulds and the molten material is fed by gravity.

Typically, small moulds below 5 kg are manipulated by hand and bigger moulds are manipulated by a machine.

These moulds are made from cast iron for small runs or Beryllium Copper for longer runs.

To create internal cavities either sand cores or metal cores are used with the sand cores allowing for more complex internal shapes that can be achieved in pressure die casting.

Tooling for both sand cores and casting moulds are designed and made on-site in our own toolroom.

Contact us regarding our custom die-casting process and die casting applications.

We provide full project consultation to help you:

At EXIPRO, Gravity Die Casting processes provide numerous benefits over other types of metalworking methods.

We used to produce parts that are finished-able to high surface finishes, pressure-tight.

-

What are the advantages of Die Casting?

At EXIPRO, Gravity Die Casting processes provide numerous benefits over other types of metalworking methods.

We use Gravity die casting to produce parts that are finished-able to high surface finishes, pressure-tight.

Gravity Die Casting Advantages

Reduced final product weight

Primary in feed material requirements reducing costs

Lower tooling costs

Suitable for long and short-run production batches

Typical Gravity die casting parts

Plumbing Valves

Mixers & Taps

Electrical Parts

Engineering Wear Parts

Architectural hardware

Decorative parts

-

What Forging processes does EXIPRO use?

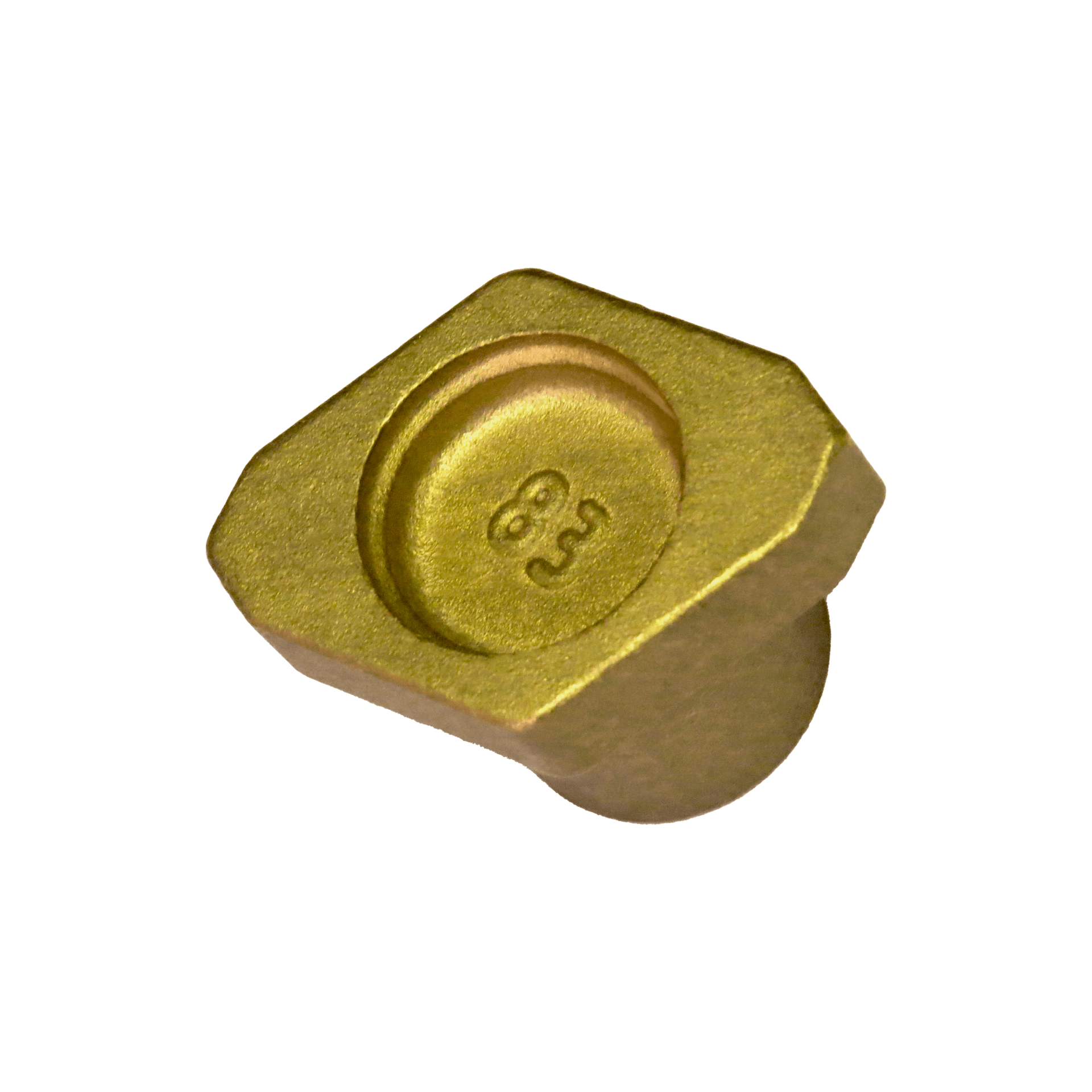

EXIPRO produces forgings from as small as 20 grams to 1 kg.

These are made using a variety of presses ranging from 100 tons to 350 tons.

The forgings can be cored to reduce weight & cost.

Forgings are made from billets, cut from extrusions where possible a standard round billet but at times due to complexity a special extruded shape is used.

Forgings are typically trimmed after forging to remove flash

All tooling is made and designed on-site.

-

What are the advantages and benefits of Brass Forged components?

Advantages

Brass forging offers a number of outstanding advantages over parts produced by other manufacturing processes such as casting. These advantages result from the inherent properties of Brass alloys plus additional improvements in mechanical and physical properties imparted by the forging process.

Custom brass forging offers excellent properties that you will not find in other processes.

Forged metal parts offer many desirable characteristics, including:

- High ductility

- Outstanding machinability

- Excellent joining and plating characteristics

- Superior polishing and finishing characteristics

- Superior mechanical properties

- High density

- Freedom from flaws

- Dimensional accuracy

- Repeatability

- Excellent surface finish

- Lustrous appearance after pickling

-

How do I know if my product-part should be a Forging ?

Many people are unable to determine when a part should be a casting or forging.

It is true as a result of the above that many parts that some unscrupulous suppliers claim are forgings are actually castings and therefore cheaper and more attractive price-wise and the customer is none-the-wiser until product failures occur.

A common example would be a brass handle where the only difference would be in the cast handles reduced ability to handle torque.

The solution

Deal with suppliers who are clear /open on pricing/process differences and be aware of pushing the price too hard forcing the supplier to misrepresent a casting as a forging.

EXIPRO has extensive experience in assisting customers in choosing between casting and forging and always openly discusses the pros and cons with the customer.

-

How do I know if my product-part should be a Casting?

As general rule castings are not used as parts that are exposed to rotational torque, twist or impact.

Gravity castings are very useful in:

Reducing the cost if a part is made by forging and has a lot of excessive material weight due to forging limitations on coring can be reduced in the casting process by utilizing a sand core.

EXIPRO has extensive experience in assisting customers in choosing between casting and forging and always openly discusses the pros and cons with the customers.

EXIPRO Brass Machining

EXIPRO has a wide variety of machining equipment in Standard and CNC Turning, Drilling, and Milling configurations as well as a variety of specialty combination machining equipment to process larger volumes in one operation.

FAQs

Got a question about EXIPRO Machining? We’re here to help.

-

Which machining processes does EXIPRO use?

EXIPRO has a wide variety of machining equipment in Standard and CNC Turning, Drilling, and Milling configurations as well as a variety of specialty combination machining equipment to process larger volumes in one operation.

EXPIRO supplies a variety of machined part parts and these are typically made from castings, forgings, bar stock, or specialty extruded shapes.

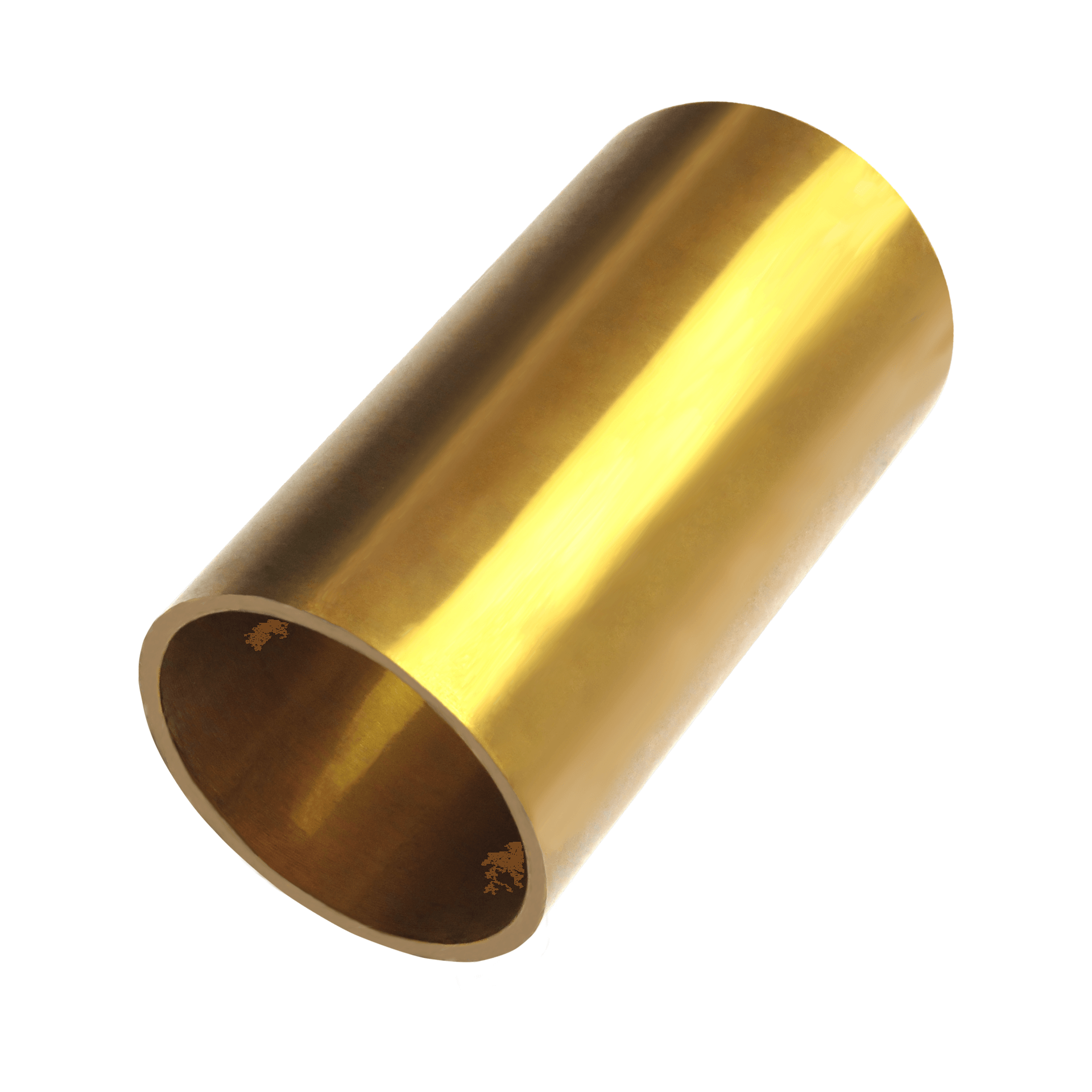

Brass parts made from the following processes can be machined :

- Castings

- Forgings

- Bar Stock

- Extruded Shapes

- Brass sheet

- Brass Tube

-

Why are different machines used for machining brass parts?

The selection of the appropriate machining process is dependent on:

- Volume

- Shape/Geometry complexity

- Tolerance requirements

-

What is EXIPRO's Brass machining capacity?

Our machining capability is very diverse and there are many processes not typical to general engineering because we work with brass which has very good machinability properties.

EXIPRO Plating & Finishing

EXIPRO provides a range of plating & finishing services and products. EXIPRO has 30 years of experience in finishing an array of parts in a huge variety of shapes and EXIPRO provides this service as a stand-alone service to many customers.

FAQs

Got a question about EXIPRO Plating & Finishing? We’re here to help.

-

What kind of finishes does EXIPRO provide?

EXIPRO provides a range of services and products in the following conditions:

- As machined with some surfaces still showing the cast surface

- As machined with some surface still showing the as forged surface

- As machined with some surfaces still showing the extrusion surface

- All the above in a highly polished surface

- All the above nickel /chrome plated

- We have access to specialty finishes via outsourcing e.g. antique /satin chrome and a huge selection of others

Inquire about EXIPRO'S finishing services

-

How does brass parts get polished?

Getting brass surfaces to a highly polished condition takes a lot of effort and skill and is typically a very big portion of the parts finished cost.

While it's true that there are some automated (non-human) polishing options it's generally accepted that the traditional sanding and buffing by hand through a series of grits on the sanding and then a sequence polishing steps achieve the best finish.

This requires skill and dexterity and takes years of experience.

Exipro has 30 years of experience on finishing on a huge variety of parts in a huge variety of shapes and in fact we provide this service as a stand-alone service to many customers

-

How do you get a good plated finish on a plated part?

Not everyone realises that under the shiny plating they see there is a highly polished brass surface.

In fact, plating does not cover up and inherent surface defects in fact it highlights them so good surface preparation is critical to a good plating finish.

-

When the term CP (abbreviation for Chrome-plating ) is used is this a definable standard?

No, it describes the process and is not a specification.

Customers should specify the standard they require and this will then give the manufacturer the clear plating thickness required.

This is the reason why we see many parts where the shiny new surface is gone within a short period of time.

EXIPRO has years of Chrome plating experience and will work with the customer to choose applicable plating specifications as well as providing guidelines on how to design to accommodate plating and assembly.

Manufacturing & Exporting of Quality Brass Components

Industries EXIPRO served

| Agriculture | Architectural & Decorative | Construction |

|---|---|---|

| Fire Protection Products | Hydraulic Fluid Power | Plumbing |