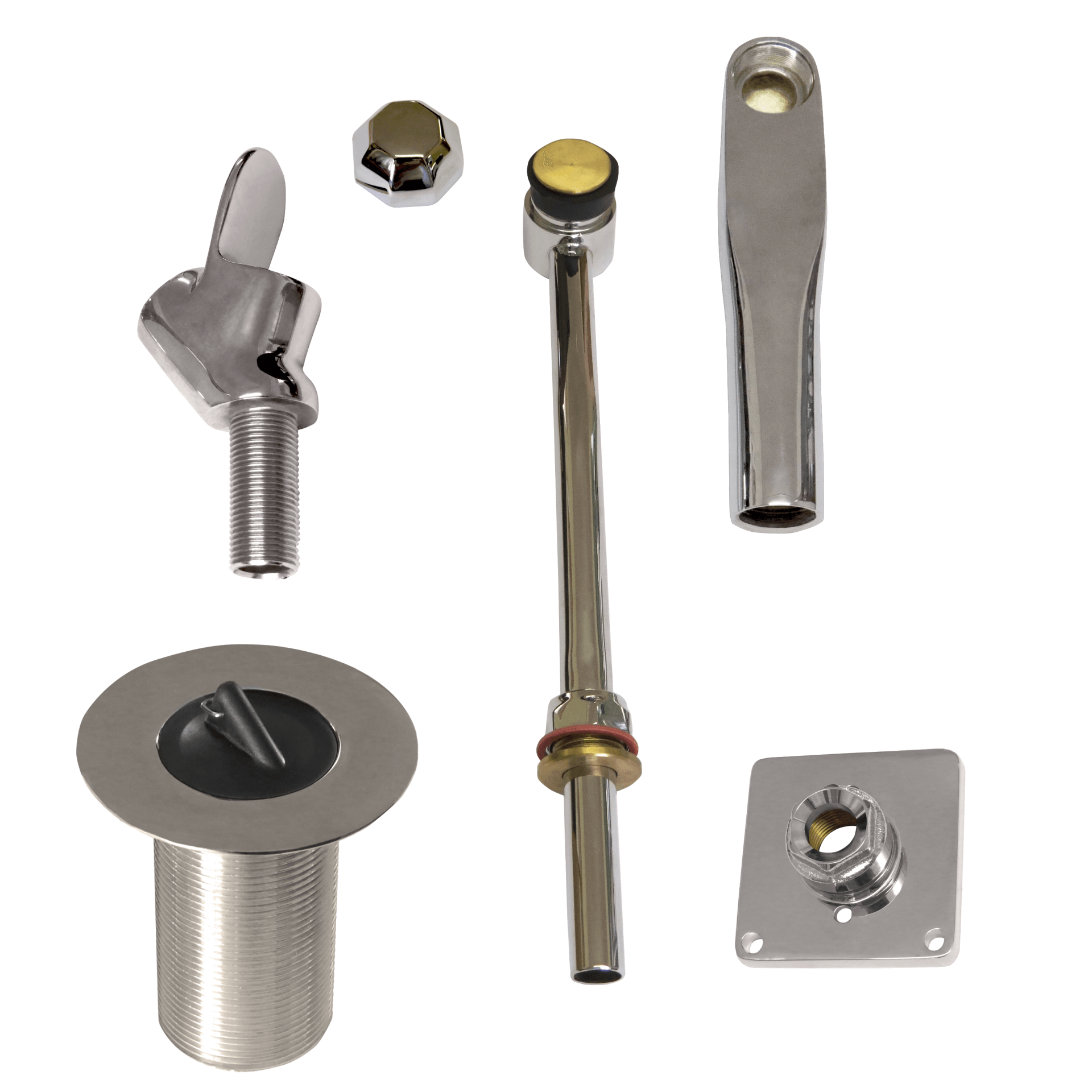

CHROME-PLATING BRASS

Brass is a versatile, binary alloy made from zinc and copper that carries multiple advantages — it's affordable, low-friction and highly machinable, and it also maintains good heat and electrical conductivity. You can utiliSe brass in various ways, but you can also add to its overall finish and properties with multiple plating processes.

How we do it?

We will begin the job by thoroughly cleaning the surface of the components with a solvent to remove dirt, debris and other kinds of grime. We might also buff the item with a polishing pad to ensure a clean surface free of imperfections, which the chrome will mirror. We'll then immerse it into a chrome bath, free of the voltage at first, to allow for warming and etching.

The electricity will begin to flow, and we'll carefully modulate the voltage to meet standard plating procedures. We'll grind down the finish post-process to eliminate any uneven buildups.

High-Quality Chrome Plating

If your project requires durable metal plating, EXIPRO Chrome can provide high-quality hard chrome plating to meet your needs. EXIPRO is a leader in industrial chrome plating, and we use our expertise to deliver top-quality hard chrome plating for any application. Because we perform our chrome plating in-house, we have precise control over the quality of your final product. To learn more about hard chrome plating from EXIPRO, contact us today

Like many plating processes, our hard chrome plating occurs in an electrochemical bath. A layer of chromium metal is applied to all surfaces exposed in the bath, allowing for plating of complex and irregular shapes including bores, holes and recesses. Our advanced chrome plating baths have been designed to give us maximum control over the plating parameters, meaning we can create the perfect thickness and hardness of coating for your application.

Once the coating is applied, you get an extremely hard surface that is more than decorative. Unlike traditional chrome plating that is extremely thin and only present for appearance reasons, our hard chrome plating significantly increases the surface hardness of your substrate metal without significantly modifying its properties. Our layer of chrome can also help reduce friction, keeping temperatures lower during equipment operation and helping extend the life of your parts and components.

You get impressive wear characteristics and corrosion resistance as well as a smooth surface that can be polished for an even smoother finish. Our hard chrome finish is popular for hydraulic cylinders, both new and remanufactured. Here at Hard Chrome Specialists, we give you greater value and help you lower operating costs while reducing downtime.

These advantages add up to big savings over time and help your plated equipment and components last longer.

Your Chrome Plating Specialist

We do in-house chrome plating to better control the thickness and quality of our final product. Thanks to our tight controls and advanced equipment, we ensure every chrome plating job exceeds your expectations and delivers the right:

- Surface hardness

- Corrosion resistance

- Appearance and finish

- Desired friction characteristics

Customers in AFRICA, SOUTH AFRICA and beyond know that we can handle a wide range of industrial plating applications. Our expert team will take the time to understand your chrome plating needs and propose the perfect solution. We continue to grow our business, thanks to our reputation as a hard chrome plating specialist and our attention to detail.

-

What is EXIPRO'S key to quality and durable Chrome-Plating

The key to quality, durable chrome plating is maintaining precise control of the chrome plating process. Our hard chrome layer is deposited using our state-of-the-art electrochemical baths. Your substrate is passed through our chromic acid bath with a controlled current creating a chemical reaction on the surface that draws chromium metal from the solution and deposits it in a fine layer.

The result is a tightly adhering hard chrome layer that offers the durability, wear, and hardness properties you require for your application. Before we start on your project, we will discuss your requirements with you and study the nature of your parts or materials to create the correct plating profile. You can specify a desired size and surface finish that matches your needs. You won't find a more reliable hard chrome specialist industrial chrome plating partner than EXIPRO.

Manufacturing & Exporting of Quality Brass Components

Industries EXIPRO served

| Agriculture | Architectural & Decorative | Construction |

|---|---|---|

| Fire Protection Products | Hydraulic Fluid Power | Plumbing |